Category: Steel Coil

Pattern Color Steel Coil

Hot-rolled round bar is formed and naturally cooled through hot-rolled finished steel, pressed low carbon steel and alloy steel in high temperature conditions, it is mainly used for the reinforcement of reinforced concrete and prestressed concrete structures, civil engineering and architecture the use of one of the largest varieties of steel.

Pattern Color Steel Coil is based on galvanized sheet, galvalume sheet, zinc-aluminum-magnesium, aluminum-zinc-magnesium, aluminum-magnesium-manganese, stainless steel as the substrate, after surface pretreatment, using a roller coating method, coated with multiple layers of liquid paint, after baking Bake and cool.It uses polyester, silicon-modified polyester, high-weather-resistant polyester, polyvinylidene fluoride, epoxy, and high-sealing corrosion-resistant coatings. It has excellent durability, corrosion resistance, and moldability(formability). Products are widely used in household appliances, decoration, construction, automotive and other industries.

| Product name | Pattern Color Steel Coil |

| Grade | TSGCC/TDX51D/TDX52D |

| Thickness | 0.09-2.0mm |

| Width | 750-1250mm |

| Coil Weight | 2-10T |

| Coil ID | 508/610mm |

| Top coating thickness | 10-30um |

| Back coating thickness | 5-25um |

| Paint type | PE/SMP/HDP/PVDF |

| Base matenal | GI/GL/GA/AL/STS |

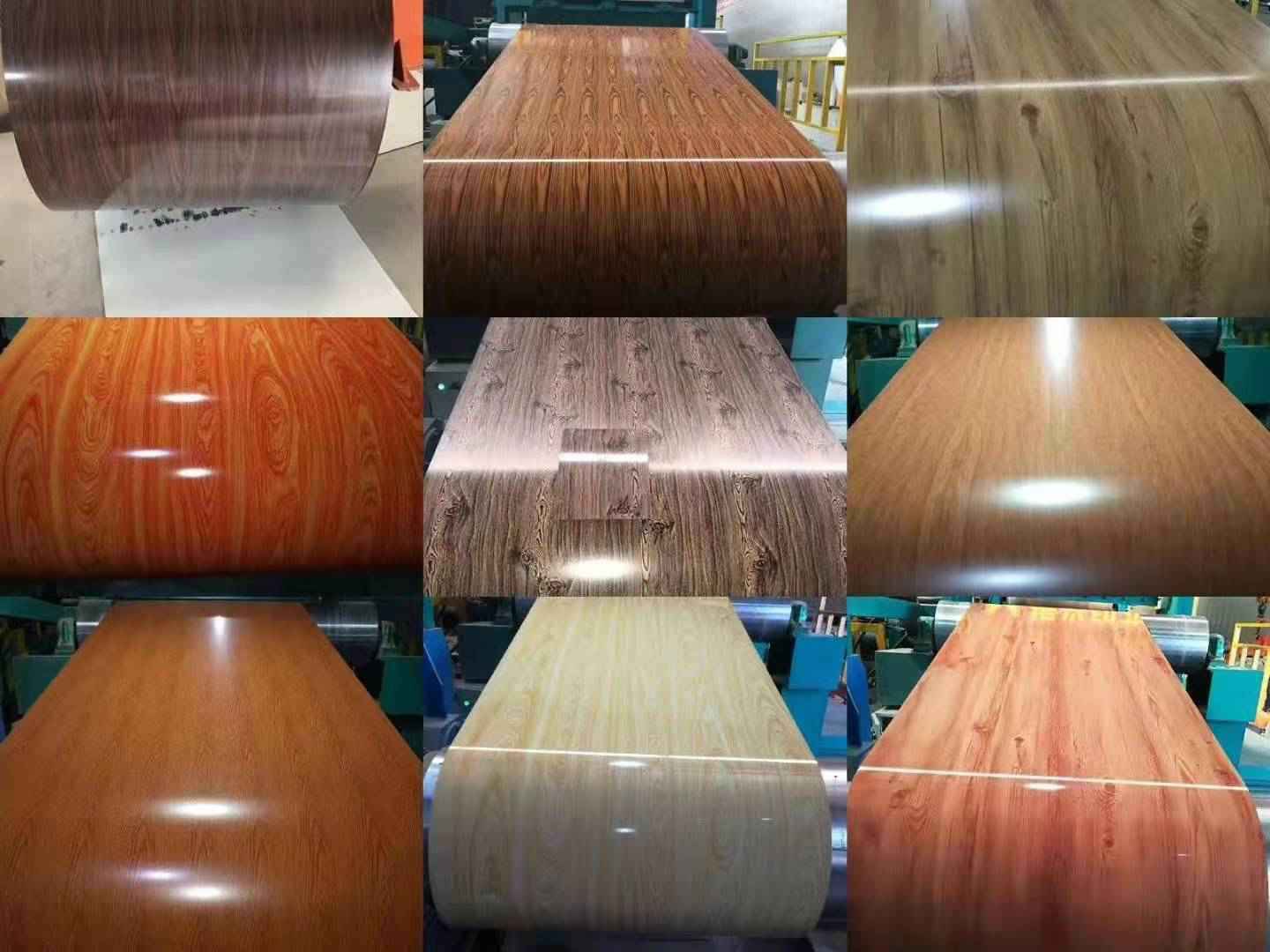

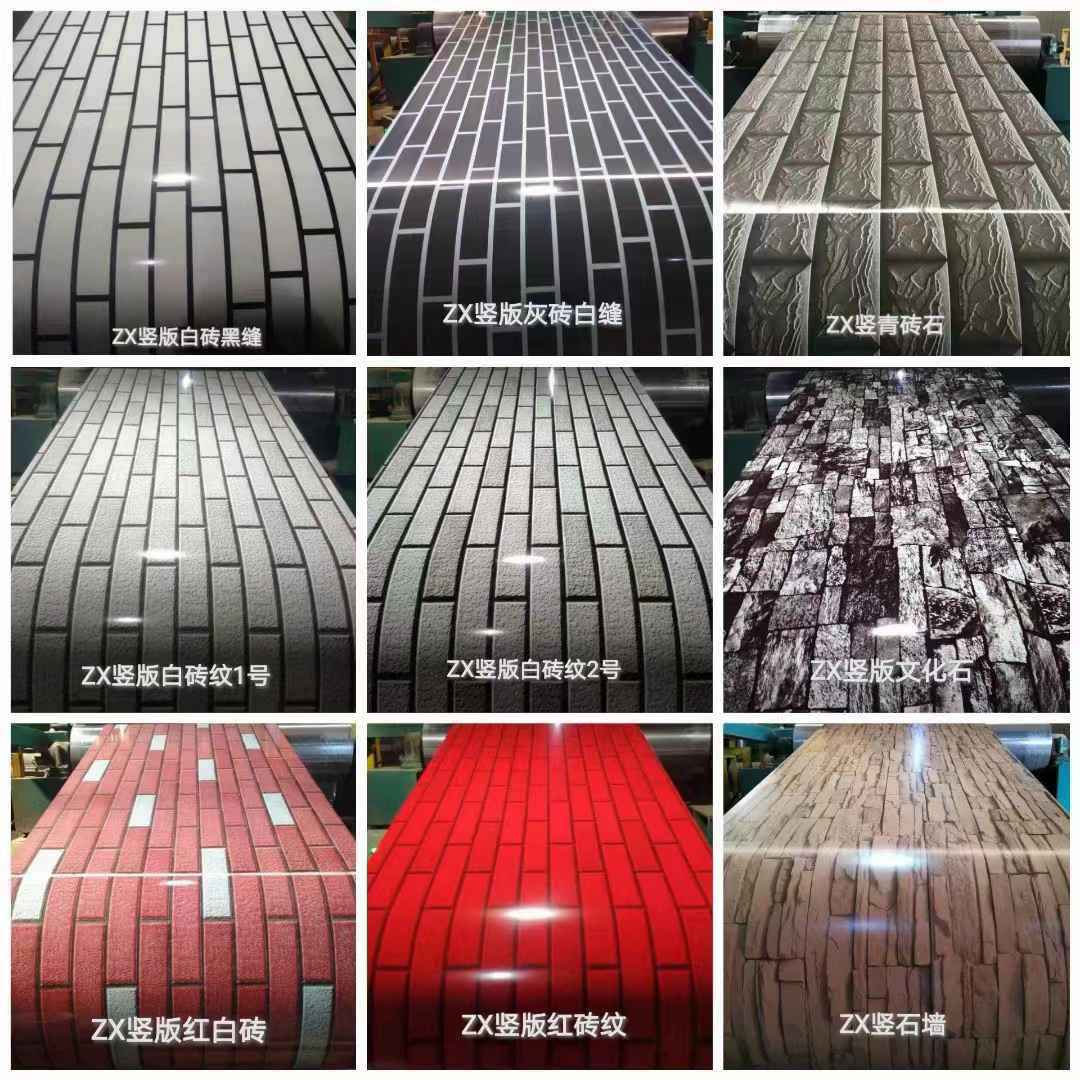

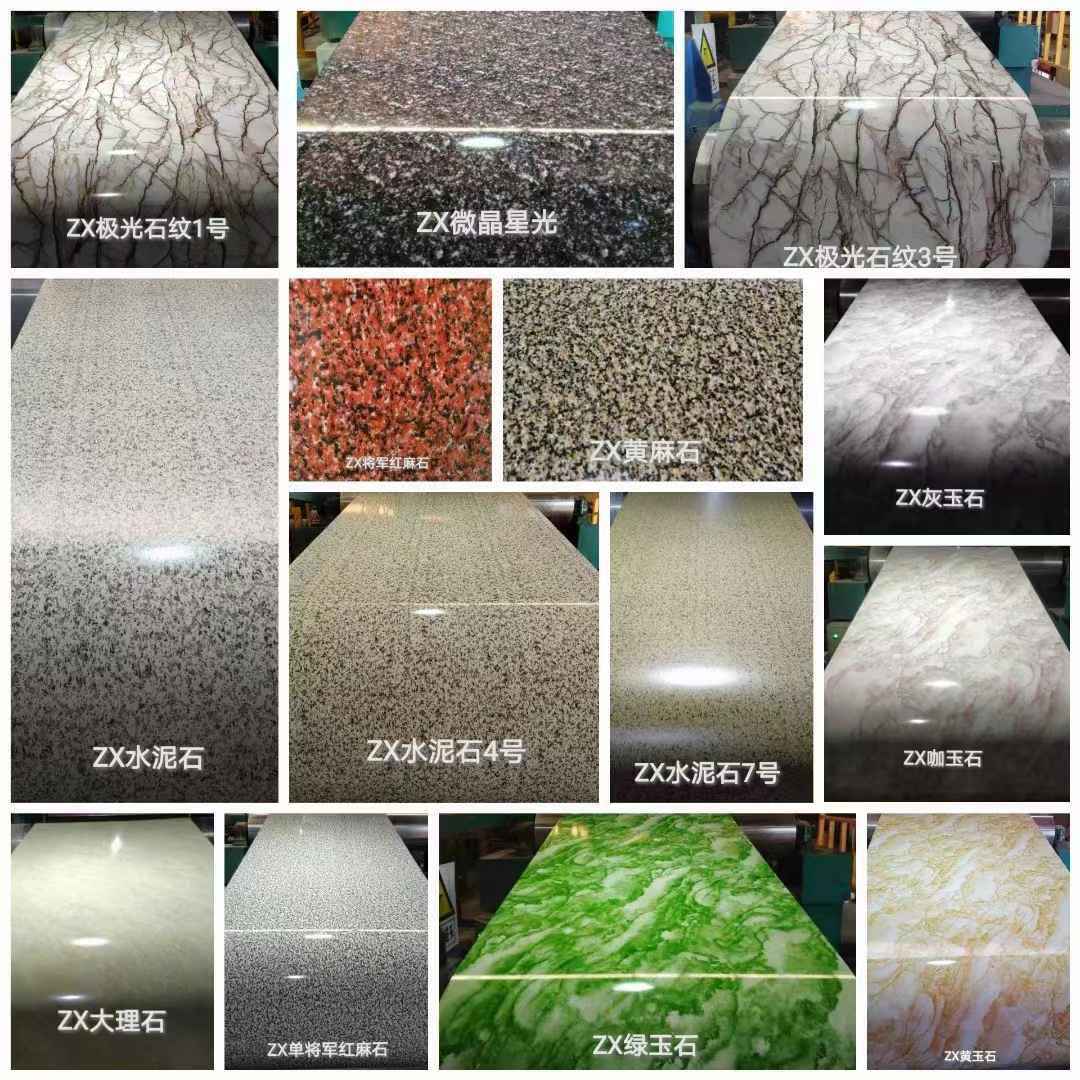

| Surface Color | RAL, wood grain pattern, camouflage pattern, stone pattern, matte pattern, high gloss pattern, flower pattern, etc |

| Annual production capacity | 1000000T |

| Place of Origin | Shandong, China |

| Production Standard | EN/GB/AISI/ASTM/DIN/JIS |

| Delivery Time | 7-15 days/According to customer requirements |

| Brand Name | Xinhe |

| Certificate | ISO9001/ISO14001/ISO45001 |

| Payment | FOB 30% deposit,70% before shipment |

| Quality assurance | According to the order requirements |

| Packaging requirements | According to the order requirements |

| Product Name | Film thicknessμm | Core performance | T bend | MEK | Neutral salt spray | QUV-A | Recommended environment |

| Self-cleaning products | ≥25 | Carbon black experiment △E<2, water contact angle ≥30 degrees | 2T | ≥100 | 1000 h | 3000 h | C3 level environment |

| Heat reflection products | ≥25 | TSR≥0.25,SRI:Light color≥78,other colours≥29 | 2T | ≥100 | 1000 h | 1500 h | C3 level environment |

| Anti-static products | ≥25 | Surface resistance 1066-1099Ω | 2T | ≥100 | 1000 h | 1500 h | C2 level environment |

| Antibacterial products | ≥25 | Activity against Staphylococcus aureus and E. coli>2 | 2T | ≥100 | 1000 h | 1500 h | C2 level environment |

| Type of coating | Recommended substrate type | Coating thicknessμm | MEK | T bend | Porosity | 5%hydrochloric acid | 5%Sodium hydroxide | Neutral salt spray | Acid salt spray | Alkaline salt spray | QUV-A | Common environment | Dedicated environment | Recommended environment |

| Polyester(PE) | Z/AZ/ZM/AZM | ≥20 | ≥100 | 3T | / | 24 h | 24 h | 1000 h | / | / | 1000 h | 10 year | / | C2 environment |

| High weather resistance(HDP) | Z/AZ/ZM/AZM | ≥23 | ≥100 | 3T | / | 24 h | 24 h | 1500 h | / | / | 1500 h | 15 year | / | C3 environment |

| Silicon Reform(SMP) | Z/AZ/ZM/AZM | ≥23 | ≥100 | 3T | / | 24 h | 24 h | 1500 h | / | / | 1500 h | 15 year | / | C2 environment |

| Fluorocarbon(PVDF) | Z/AZ/ZM/AZM | ≥25 | ≥100 | 2T | / | 24 h | 24 h | 2000 h | / | / | 3000 h | 20~30 year | / | C4 environment |

| Polyurethane(PU) | Z/AZ/ZM/AZM | ≥40 | ≥100 | 2T | / | 24 h | 24 h | 720 h | / | / | 1000 h | 10~20 year | / | C2 environment |

| Hot film(VCM) | Z/AZ/ZM/AZM | ≥100 | / | 0T | / | 360 h | / | / | / | / | / | 10 year | / | C2 environment |

| Color printing | Z/AZ/ZM/AZM | ≥25 | ≥100 | 3T | / | 24 h | 24 h | 600 h | / | / | 1000 h | 10 year | / | C2 environment |

| Reticulated, suede | Z/AZ/ZM/AZM | ≥25 | ≥100 | 2T | / | 24 h | 24 h | 1000 h | / | / | 1000 h | 10 year | / | C2 environment |

| High corrosion-resistant polyester | Z/ZM/AZM | ≥25 | ≥1000 | 3T | 90V No breakdown | 120 h | 120 h | 2000 h | 1500 h | 1500 h | 2000 h | 15 year | 10 year | C5 environment |

| (PE•Pro) | ||||||||||||||

| High corrosion resistance and weather resistance polyester(HDP•Pro) | Z/ZM/AZM | ≥25 | ≥1000 | 3T | 90V No breakdown | 120 h | 120 h | 2500 h | 2000 h | 2000 h | 3000 h | 20 year | 15 year | C5 environment |

| Super corrosion resistant super weather resistant polyester(HDP•Plus) | Z/ZM/AZM | ≥30 | ≥1000 | 3T | 90V No breakdown | 360 h | 360 h | 4000 h | 3000 h | 3000 h | 4000 h | 25 year | 20 year | C5 environment |

| High corrosion resistance fluorocarbon aluminum magnesium manganese(PVDF•Pro) | Aluminum magnesium manganese | ≥25 | ≥1000 | 2T | 90V No breakdown | 240 h | 240 h | 10000 h | 5000 h | 5000 h | 10000 h | 50 year | / | Key industrial engineering, |

| National public projects | ||||||||||||||

| Super corrosion-resistant nano-fluorocarbon aluminum magnesium manganese(PVDF•Plus) | Aluminum magnesium manganese | ≥30 | ≥1000 | 2T | 90V No breakdown | 480 h | 480 h | 20000 h | 10000 h | 10000 h | 15000 h | 70 year | / | Key industrial engineering, |

| National public projects | ||||||||||||||

| Centennial stainless steel fluorocarbon(PVDF•Plus) | Stainless steel | ≥30 | ≥1000 | 2T | 90V No breakdown | 480 h | 480 h | 30000 h | 10000 h | 10000 h | 15000 h | 100 year | / | Key industrial engineering, |

| National public projects | ||||||||||||||

| High corrosion-resistant epoxy back paint | / | ≥12 | ≥100 | 4T | 67.5V No breakdown | 120 h | 120 h | 2000 h | 1500 h | 1500 h | / | / | / | Supporting the use of |

| Super corrosion-resistant epoxy back paint | / | ≥20 | ≥100 | 3T | 90V No breakdown | 240 h | 240 h | 3000 h | 2500 h | 2500 h | 2000 h | / | / | Supporting the use of |

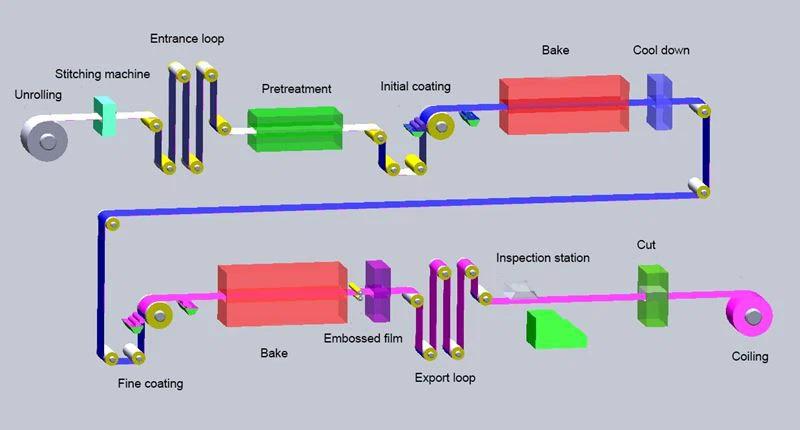

2)Production process

Welding →Inlet Looper→Pre-treatment→Primer coat→Baking→Cooling→Uncoiling→Finish coat→Baking→Embossed or film→QC→Coiling.

3) COILS TEST

| Paint thickness:10-30um as your require |

| Glossy: Highlight(70-95), Matte(lower than 40), Medium gloss(40-60) as your requirment. |

| T-bending:0-3T as required |

| Wipe: can reach 200 times |

| Natural Salt Spray: More than 1000 hours. It is decided by paint thickness and different paint.PE more than 1000 hours.HDP more than 1500 hours. PVDF more than 2000 hours. |

| UV light experiment: for regular paint, not less than 500 hours.For matt and high paint, not less than 1000 hours |

| Our Advantage |

| 15years experience |

| Free sample offered |

| 6 product-lines |

| exported to 60+ countries |

| Factory direct supply |

| 7*24 Professional service |

Contact us Form

"*" indicates required fields