Category: Steel Coil

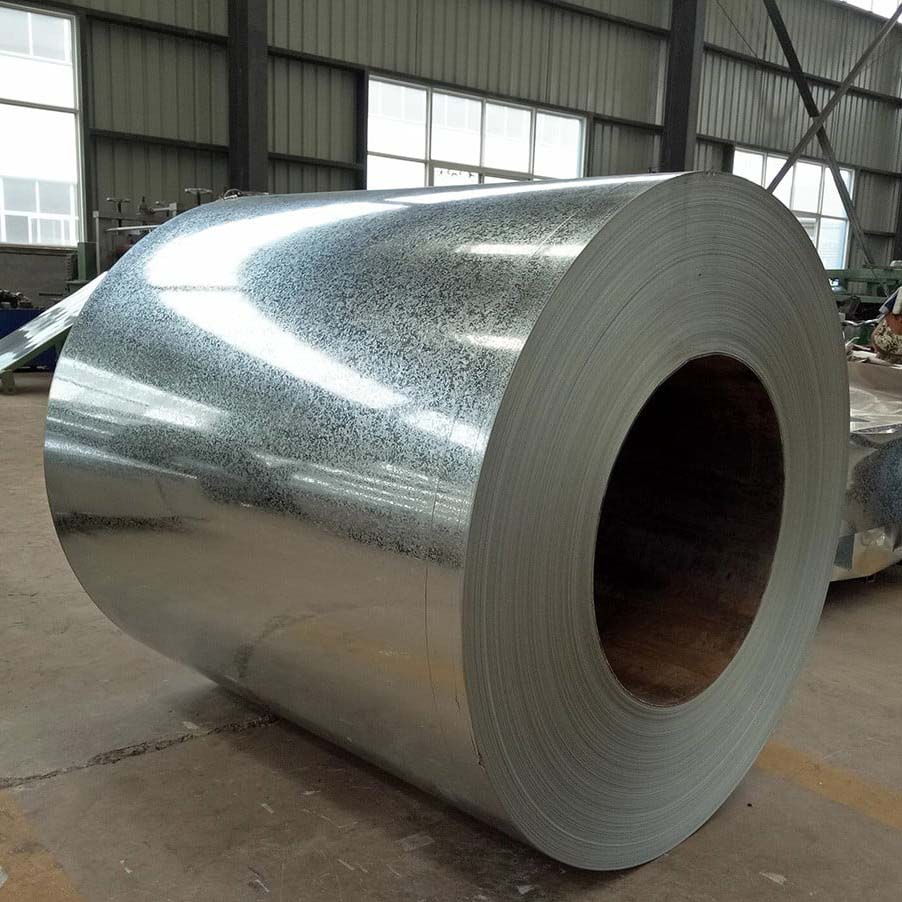

Galvanized Coil

Hot-dip galvanized and zinc-iron alloys have excellent performances, good corrosion resistance, forming, coating and other comprehensive properties, and are mainly used in construction, household appliances, automobiles, and metallurgy industries.Among them, being mainly used for roofs, doors and windows, shutter doors, ceiling keels, etc in the construction industry.; being used in refrigerators in Home appliances, washing machines, etc.; being mainly used for body shells, chassis, doors, fuel tanks, fenders, etc in the automotive industry. being mainly used for steel window blank, color coated plate substrate and so on in the metallurgical industry.

| Product name | Galvanized sheet |

| Grade | SGCC/DX51D/DX52D |

| Thickness | 0.09-2.0mm |

| Width | 750-1250mm |

| Coil Weight | 2-10T |

| Coil ID | 508/610mm |

| Base matenal | GI/GL/GA/AL/STS |

| Coating | Z20-Z275 |

| Annual production capacity | 1000000T |

| Place of Origin | Shandong, China |

| Production Standard | EN/GB/AISI/ASTM/DIN/JIS |

| Delivery Time | 7-15 days/According to customer requirements |

| Brand Name | Xinhe |

| Certificate | ISO9001/ISO14001/ISO45001 |

| Payment | FOB 30% deposit,70% before shipment |

| Quality assurance | According to the order requirements |

| Packaging requirements | According to the order requirements |

| Product Name | Grade | Yield Strength/Mpa | Tensile strength/Mpa | Elongation after breaking/% |

| Low-carbon steel | DX51D+Z | ≤360 | ≤440 | ≥20 |

| DX52D+Z | ≤260 | 300-390 | ≥28 | |

| Gapless atomic steel | DX53D+Z | ≤200 | 270-320 | ≥38 |

| DX54D+Z | ≤180 | 270-310 | ≥40 | |

| Structural steel | S250GD+Z | ≥250 | ≥330 | ≥19 |

| S350GD+Z | ≥350 | ≥420 | ≥16 | |

| S450GD+Z | ≥450 | ≥510 | ≥14 | |

| S550GD+Z | ≥550 | ≥560 | / |

PRODUCT DETAIL

1)What is GI(galvanized steel coil)

For galvanized steel coils, the thin steel sheet is immersed in the molten zinc tank so that a thin sheet with a zinc layer adheres to the surface. Therefore, it is mainly produced by the continuous galvanizing process; the coiled steel sheet is continuously immersed in a galvanized bath with molten zinc to make it an alloyed galvanized steel sheet.

2)Production process

Cold Rolled Steel Coil(CRC)→Decoil→Entry Looper→Skim→Cleaning→Air Dry→Annealing→Zinc Pot→Air Cooling→Leveller→Chromated→Dry→Exit Looper→Colling→Packing

PRODUCT FEATURE AND APPLICATION

1) Zinc Spangle:Big Spangle and zero spangle are popular

2)Surface treatment:

1 PassivationPassivation treatment of the galvanized layer can reduce folding rust (white rust) under moisture storage and transportation conditions.

2 OilingOiling can reduce the steel plate’s corrosion. After the passivation treatment of steel plates and strips, repainting oil will further reduce corrosion under humid storage conditions.

3 Lacquer sealCoating a fragile transparent organic coating film can provide an additional anti-corrosion effect, especially fingerprint resistance. In addition, it can improve lubricity during molding and serve as an adhesion base layer for subsequent coatings.

4 PhosphatingVarious coating types of galvanized steel sheets can be coated through phosphating treatment without further treatment except for regular cleaning. This treatment can improve the coating adhesion and corrosion resistance and reduce the risk of corrosion during storage and transportation. Finish phosphating can be used with a suitable lubricant to improve molding performance.

3)Application

After corrugated, it can be used as a wall roof, roof panels, and fences. Mainly used in construction

TEST

HARDNESS TEST

ZINC COATING TEST

SALT SPRAY TEST,

TENSILE TEST

THICKNESS TEST

PACKAGE

The moisture-proof paper and waterproof plastic film are used as a protective layer around the product to prevent any moisture from seeping in during transportation. The outsourcing iron sheet is a sturdy material that provides additional strength and durability to the packaging.

Standard seaworthy export packing includes using a metal steel belt to secure the packaging and prevent any damage during transportation.

There should be at least four horizontal straps and three longitudinal straps to provide maximum support and stability to the packaging.These packaging standards ensure that the product is well protected and arrives at its destination in good condition, without any damage or deterioration due to environmental factors such as moisture, water, or external pressure.

WHY CHOOSE US:

1. We have been exporting steel coil for 15 years, the clients from all over the world.

2. Exported to more than 60 countries, especially Africa, South America, and Southeast Asia.

3. China government support enterprise with 30 engineers,50 bachelor’s degree office staff, and 300 production workers.

4. We have 6 product lines,2 hot-dipped galvanized steel lines, 2 galvalume steel lines, and 2 Prepainted galvanized/galvalume steel coil , with an output of 9,00,000MT/YEAR.

Hot Tags: galvanized steel coil, China, suppliers, manufacturers, factory, customized, price, in stock, free sample, Pattern Steel Coil, Color Coating Steel Coil, Hot Dipped Galvanized Steel Coil, GI Steel Coil, Hot Dip Galvanized Coils, Galvanized Steel Coil

Contact us Form

"*" indicates required fields