Category: Steel Coil

Galvalume Coil

Galvanized and Galvalume steel coils possess unique properties such as durability, excellent corrosion resistance, and lightweight. They are easy to fabricate and fire-resistant, making them a versatile choice for a wide range of applications. Galvalume steel coils have enhanced resistance due to the presence of aluminum.

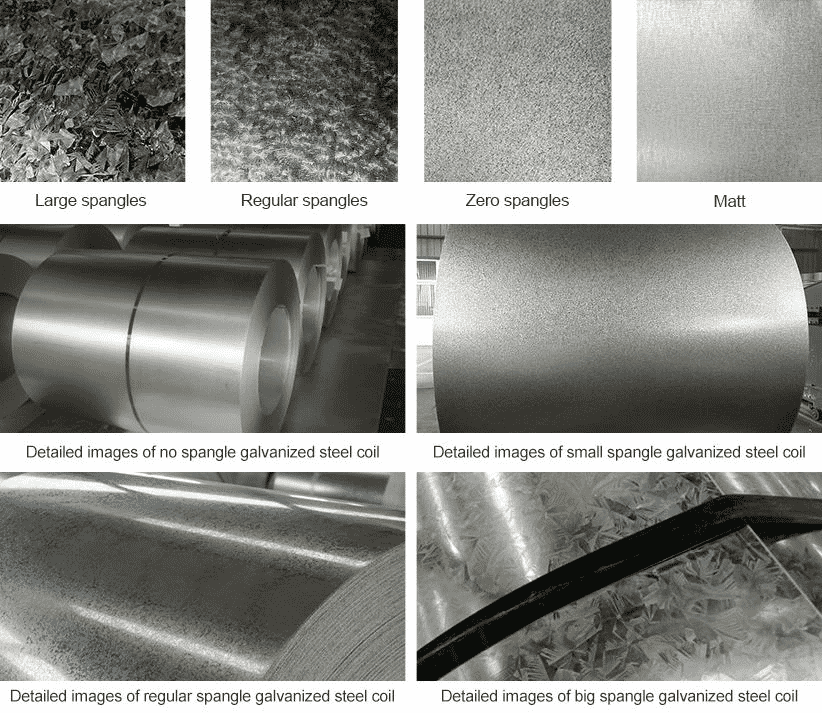

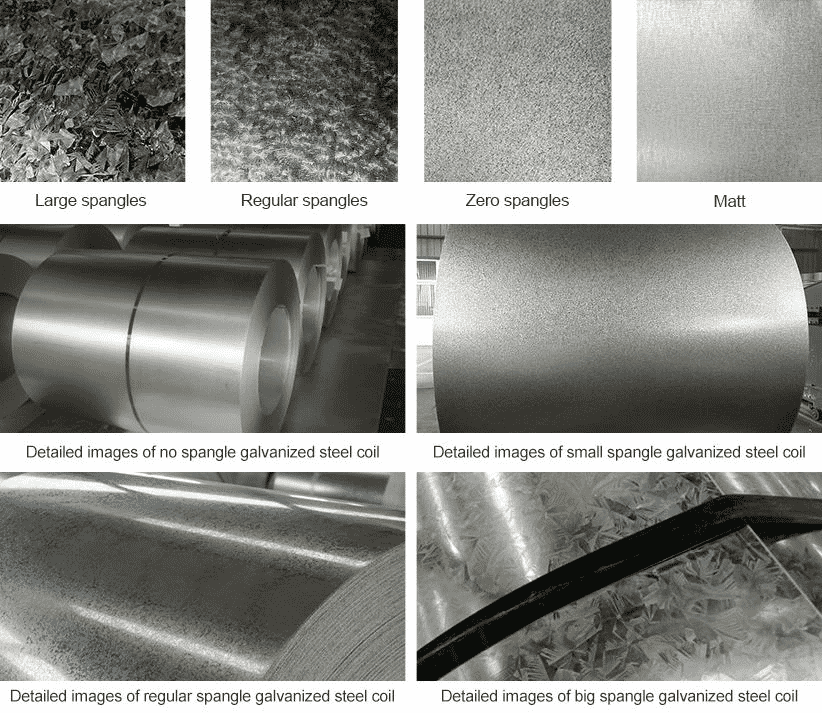

The aluminum-zinc-plated steel alloy coating is composed of about 55% aluminum, about 43.5% zinc, and about 1.5% silicon. Compared with traditional galvanized products, it has more excellent corrosion resistance, heat resistance, heat reflectivity and other characteristics. The zinc flower(spangle) on the surface of the aluminum-plated zinc plate is small and uniform, with bright colors and high surface hardness. It can be coated with fingerprint-resistant semi-permeable membranes of various colors, and is widely used in household appliances, construction, structure, electrical and other industries.

| Product name | Zincalume plate |

| Grade | SGCC/DX51D/DX52D |

| Thickness | 0.09-2.0mm |

| Width | 750-1250mm |

| Coil Weight | 2-10T |

| Coil ID | 508/610mm |

| Base matenal | GI/GL/GA/AL/STS |

| Coating | Z20-Z275 |

| Annual production capacity | 1000000T |

| Place of Origin | Shandong, China |

| Production Standard | EN/GB/AISI/ASTM/DIN/JIS |

| Delivery Time | 7-15 days/According to customer requirements |

| Brand Name | Xinhe |

| Certificate | ISO9001/ISO14001/ISO45001 |

| Payment | FOB 30% deposit,70% before shipment |

| Quality assurance | According to the order requirements |

| Packaging requirements | According to the order requirements |

| Product Name | Grade | Yield Strength/Mpa | Tensile strength/Mpa | Elongation after breaking/% |

| Low-carbon steel | DX51D+AZ | ≤360 | ≤440 | ≥20 |

| DX52D+AZ | ≤260 | 300-360 | ≥28 | |

| Gapless atomic steel | DX53D+AZ | ≤200 | 270-320 | ≥38 |

| DX54D+AZ | ≤180 | 270-310 | ≥40 | |

| Structural steel | S250GD+AZ | ≥250 | ≥330 | ≥19 |

| S350GD+AZ | ≥350 | ≥420 | ≥16 | |

| S450GD+AZ | ≥450 | ≥510 | ≥14 | |

| S550GD+AZ | ≥550 | ≥560 | / | |

| Special material for keel | LG550GD+AZ | ≥550 | ≥560 | ≥5 |

| Features |

| Excellent corrosion resistance. |

| good heat resistance |

| Good adhesion between coating and paint film |

| has good processing properties, |

| Can be punched, sheared, welded, etc.; |

| The surface conductivity is excellent. |

| The Difference Between Galvanized Sheet And Aluzinc Galvalume Steel Coil |

| The biggest difference between galvanized sheet and aluzinc galvalume steel coil is the difference in the coating. The galvanized sheet surface is evenly distributed with a layer of zinc material, which plays an anodic protection role for the base metal, which plays an anodic protection role for the base metal, the alternative corrosion protection of zinc material. The base metal can be damaged only when the zinc is completely corroded. |

| The surface coating of the galvalume steel sheet is composed of 55% aluminum, 43.5% zinc, and a small number of other elements. The surface of the galvanized coating is a honeycomb structure at the microscopic level. The “honeycomb” composed of aluminum contains zinc. In this case, although the aluminum-zinc coating also plays the role of anodic protection, due to the less zinc content and the zinc material is not easily electrolyzed by aluminum, the role of anodic protection is significantly reduced. Therefore, once the galvalume steel sheet is cut, it will rust quickly when the cut edge is lost to be protected, so the galvalume steel sheet should be cut as little as possible. The service life of the board is extended. |

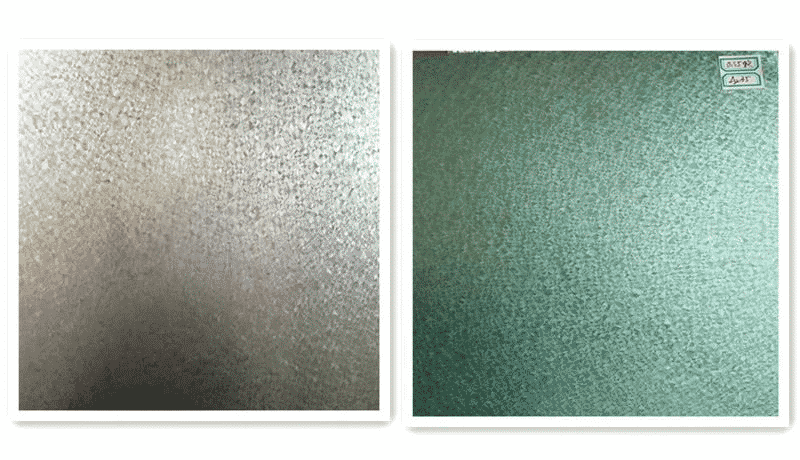

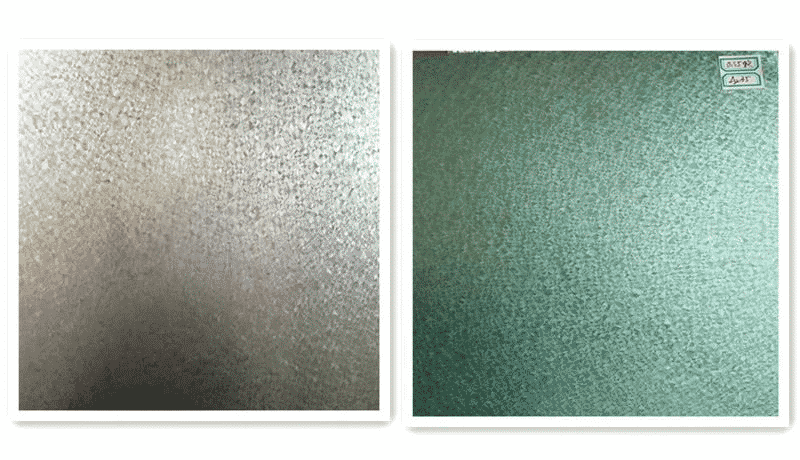

| Antifinger/Non-Antifinger |

| Galvalume steel sheets can be divided into anti-finger(AFP) and Non-antifungal. |

| Anti-finger includes color anti-finger and colorless anti-finger. |

| Anti-fingerprint refers to coating a layer of anti-fingerprint liquid on the surface of a galvalume steel coil to prevent oxidation. Since human sweat and aluminized zinc are easily oxidized, a layer of anti-fingerprint liquid is applied to increase the service life of the Galvalume steel sheet. |

Contact us Form

"*" indicates required fields